In the ever-evolving pharmaceutical industry, reliability, quality, and seamless integration across the supply chain are critical factors. At Farmson Basic Drugs, we take pride in being the only global pharmaceutical company with complete end-to-end integration in the production of Paracetamol, ensuring superior quality and an uninterrupted supply chain.

A Fully Integrated Approach – From Raw Materials to Finished Products

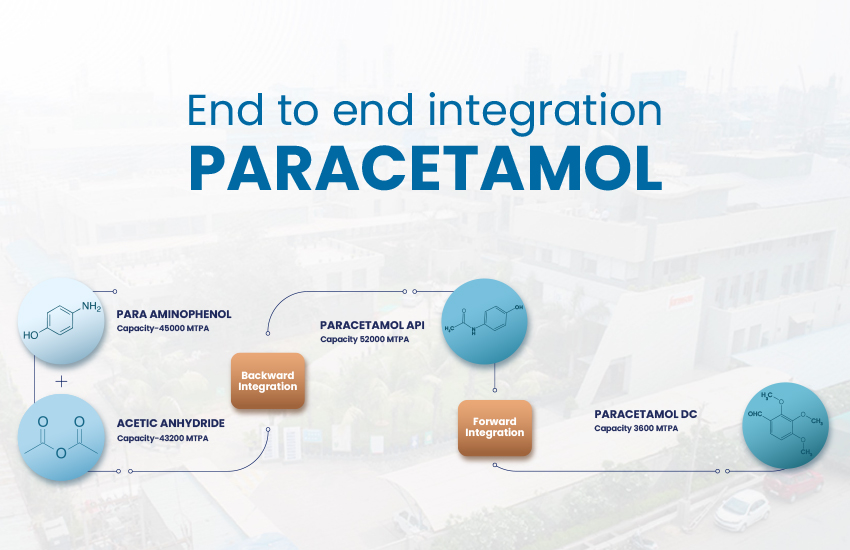

Our holistic approach begins with backward integration, securing a stable and sustainable supply of raw materials essential for Paracetamol production. It then extends to forward integration, where we manufacture Directly Compressible (DC) Paracetamol, enhancing formulation efficiency for pharmaceutical companies worldwide.

Backward Integration – Securing Raw Material Supply

To maintain consistency, cost-effectiveness, and quality in Paracetamol production, we have established large-scale facilities dedicated to key raw materials:

- Para-Aminophenol (PAP): With a massive capacity of 45,000 MTPA, we ensure a steady and high-quality supply of this crucial intermediate for Paracetamol.

- Acetic Anhydride: Our capacity of 43,200 MTPA guarantees a reliable flow of this essential reagent, further reinforcing our self-reliant production model.

By controlling these core raw materials in-house, we eliminate dependency on external suppliers, mitigating risks related to price fluctuations, supply chain disruptions, and quality inconsistencies.

Paracetamol API – Delivering Quality at Scale

Farmson Basic Drugs is a globally trusted name in the production of Paracetamol API (Active Pharmaceutical Ingredient). With an impressive manufacturing capacity of 52,000 MTPA, we cater to the needs of pharmaceutical companies across the globe, ensuring high purity, compliance with international standards, and timely delivery.

Forward Integration – Advancing Pharmaceutical Formulations

Beyond producing Paracetamol API, we have taken a step further in forward integration by manufacturing Paracetamol DC (Directly Compressible). Our Paracetamol DC capacity of 3,600 MTPA supports pharmaceutical companies in achieving enhanced tablet compression efficiency, uniformity, and superior drug formulations.

With Paracetamol DC, manufacturers benefit from:

- Faster and more efficient tablet production

- Improved compressibility and flowability

- Consistency in drug formulation

- Reduction in additional excipient requirements

Why End-to-End Integration Matters?

By seamlessly integrating the entire Paracetamol production chain, Farmson Basic Drugs guarantees:

- Unmatched reliability: With in-house control over raw materials and production, we ensure consistent supply and pricing stability.

- Superior quality: Our stringent quality control at every stage results in high-purity Paracetamol products that meet global regulatory standards.

- Sustainability: By reducing external dependencies, optimizing processes, and minimizing environmental impact, we create a sustainable pharmaceutical ecosystem.

- Competitive advantage: End-to-end integration allows us to streamline operations, reduce lead times, and enhance cost efficiency, offering better value to our customers.

Setting the Global Benchmark in Paracetamol Production

At Farmson Basic Drugs, our commitment to excellence, innovation, and self-reliance drives our leadership in the Paracetamol industry. With state-of-the-art manufacturing facilities, industry expertise, and global reach, we continue to shape the future of Paracetamol production, ensuring an unwavering supply of high-quality pharmaceutical ingredients.

For more information about our integrated Paracetamol solutions, reach out to us today!

Posted by

Posted by